Tap the “Select Size” button below to start your order.

FEATURES

HAVOC – Solid Carbide Drills

Engineered by New Generation Tools (NGT), the HAVOC Series delivers high-performance drilling with precision, speed, and durability — built for demanding industrial and production environments.

Efficient Chip Evacuation

Optimized flute geometry ensures clean and fast chip removal, preventing clogging during high-speed operations.

Customizable Configurations

Available in L/D 3, L/D 5, L/D 8, and L/D 12 variants, with options for internal coolant and non-coolant applications.

High Tool Life

Advanced carbide grade and coating ensure longer tool life, reduced wear, and consistent performance in long production runs.

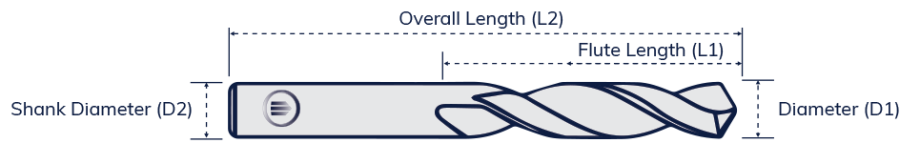

Tool Technical Diagram

Tool Features & Application

Available Variants

Explore the available variants of our tools, designed to suit diverse machining needs and material requirements.

With Internal Coolant

Designed for enhanced chip evacuation, heat resistance, and extended tool life in deep drilling operations.

Without Internal Coolant

Ideal for shallow drilling, offering cost-effective performance with the same level of precision and durability.

Want to Order Online?

Follow these simple steps to customize, order, and receive your HAVOC + tool right at your doorstep.

Select the desired size, variant, and enter the detailed diameter (D1).

Add the tool to your cart, then fill in your contact and delivery address.

Review everything and confirm your order securely. Your tool will be shipped and delivered to your doorstep.

L/D 3 Drills

| Diameter (D1) | Flute Length (L1) | Overall Length (L2) | Shank Diameter (D2) |

|---|---|---|---|

| 3.0 to 3.7 | 20 | 62 | 6 |

| 3.8 to 4.7 | 24 | 66 | 6 |

| 4.8 to 6.0 | 28 | 66 | 6 |

| 6.1 to 8.0 | 41 | 79 | 8 |

| 8.1 to 10 | 47 | 89 | 10 |

| 10.1 to 12 | 55 | 102 | 12 |

| 12.1 to 14 | 60 | 107 | 14 |

| 14.1 to 16 | 65 | 115 | 16 |

| 16.1 to 18 | 73 | 123 | 18 |

| 18.1 to 20 | 79 | 131 | 20 |

L/D 5 Drills

| Diameter (D1) | Flute Length (L1) | Overall Length (L2) | Shank Diameter (D2) |

|---|---|---|---|

| 3.0 to 3.7 | 28 | 66 | 6 |

| 3.8 to 4.7 | 36 | 74 | 6 |

| 4.8 to 6.0 | 44 | 82 | 6 |

| 6.1 to 8.0 | 53 | 91 | 8 |

| 8.1 to 10 | 61 | 103 | 10 |

| 10.1 to 12 | 71 | 118 | 12 |

| 12.1 to 14 | 77 | 124 | 14 |

| 14.1 to 16 | 83 | 133 | 16 |

| 16.1 to 18 | 93 | 143 | 18 |

| 18.1 to 20 | 101 | 153 | 20 |

Energy Industry

Our cutting tools offer precision, strength, and durability, making them suitable for demanding drilling operations in the energy sector.

Automotive Industry

Designed for high-volume production, delivering accuracy, efficiency, and consistent performance in automotive manufacturing.

Aerospace Industry

High-strength cutting performance ensuring dimensional accuracy and reliability for aerospace components.

Medical Industry

Exceptional precision and repeatability to meet the stringent requirements of medical device manufacturing.

Railway Industry

Robust tool performance ensuring durability and accuracy for critical railway infrastructure components.

Defence Industry

Engineered for reliability and strength, meeting rigorous defence manufacturing standards.

Die and Mold Industry

Ideal for precision machining of complex die and mold components with excellent surface finish.

Need Support?

Talk to Our Tooling

Experts!

Not sure which variant suits your machine or material? Reach out to our in-house experts who can guide you in selecting the best drill configuration for your production setup.